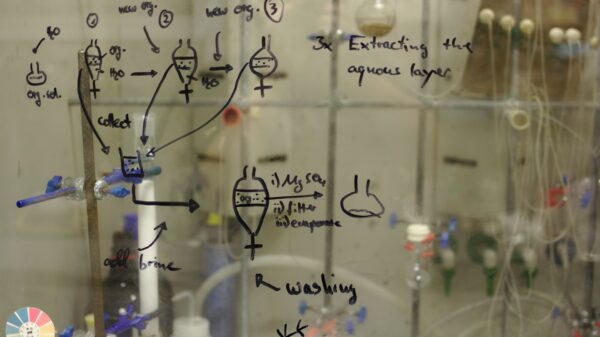

Under the US CHIPS Act, the National Semiconductor Technology Center (NSTC) is poised to emerge as a public-private consortium, comprising stakeholders from government, industry, academia, entrepreneurship, labour representatives, and investors, with the aim of advancing innovation from research laboratories to manufacturing facilities.

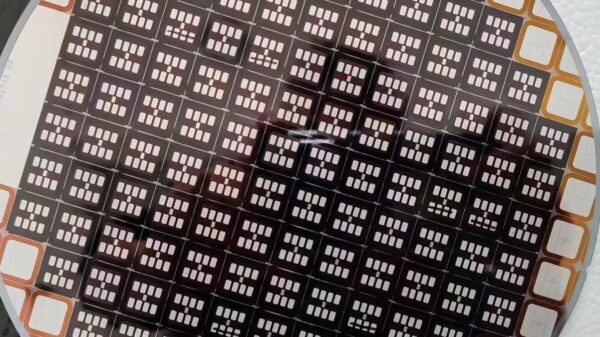

Experts highlight the importance of expanding domestic manufacturing capacity to lessen dependence on offshore production. Majority of semiconductor manufacturing takes place overseas, with an even higher reliance on foreign resources for packaging, advanced packaging, and heterogeneous integration.

Several industry groups, such as the American Semiconductor Innovation Coalition (ASIC) and MITER Engenuity, have put forward recommendations for the. . .