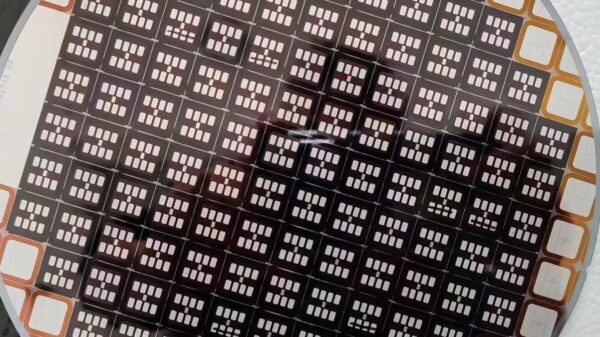

Recognising the strategic importance of semiconductor package technology, the South Korean government is set to pioneer extensive research and development (R&D) ventures in an attempt to bridge the gap with international market leaders, such as Taiwan's TSMC. This new endeavour aims to not only harness advanced technologies in specialised areas but also take the helm as a primary innovator.

The R&D project, budgeted at an upper limit of 500 billion won ($390.6 million), necessitates the clearance of a preliminary feasibility study. According to authoritative sources within the Ministry of Trade, Industry and Energy, the. . .