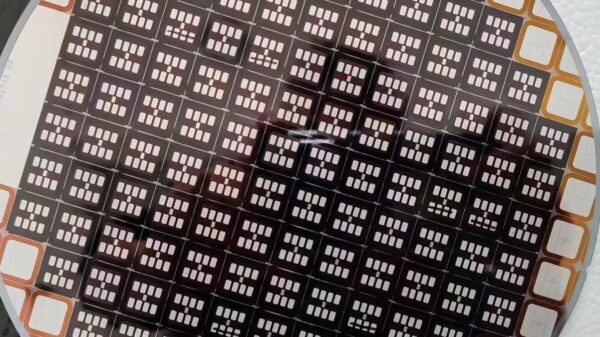

Semiconductor and display equipment manufacturers are increasingly entering the lithium-ion battery market, seeking opportunities in this relatively booming sector compared to the recession-hit semiconductor and display markets. The development of lithium-ion battery-related equipment using existing technologies is less difficult, with lower barriers to entry.

Industry sources report that semiconductor and display equipment manufacturers are diversifying their businesses into the lithium-ion battery market. Shinsung ENG, a specialist in clean rooms and renewable energy, is working to expand its dry room orders, particularly in overseas markets. Dry rooms, which control humidity in lithium-ion battery manufacturing environments. . .