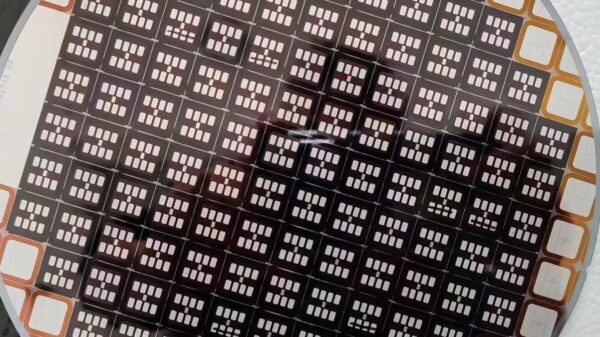

The semiconductor shortage, which began in early 2021, has left equipment manufacturers grappling to meet production plans and sparked questions about its end. Rumors in the automotive sector suggest the shortage may persist for years. This article delves into the causes, current state, and future prospects of the semiconductor shortage.

The shortage has significantly impacted the auto industry, which primarily relies on microcomputers, analog, and discrete devices, in contrast to PCs and smartphones that demand more memory and logic. In-vehicle systems, responsible for controlling functions like running, turning, and stopping, are less dependent on memory and logic, linking them. . .