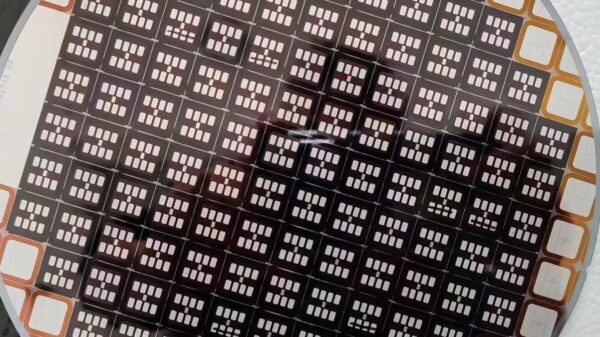

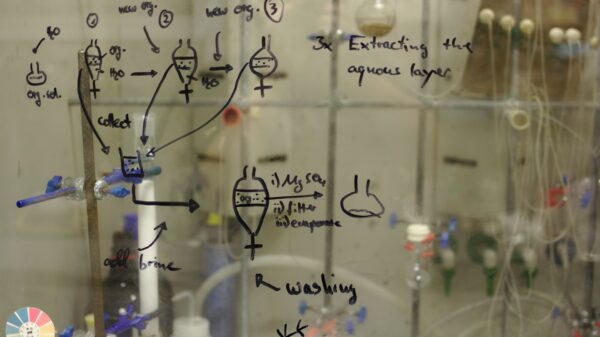

Samsung Electronics is bolstering the implementation of automation systems within its sub-fabrication facilities, which are responsible for providing specialised gases and chemicals used in semiconductor manufacturing. The company has already integrated automated systems in new facilities, such as the Pyeongtaek V1 fab, and is progressively introducing them to legacy facilities.

The principal objective behind the adoption of sub-fab automation is to enhance safety and avert accidents. This initiative is a response to the Severe Disaster Punishment Act, which came into force in the previous year.

Samsung is deploying an Automatic Clean Coupler (ACQC) system and a drum logistics. . .