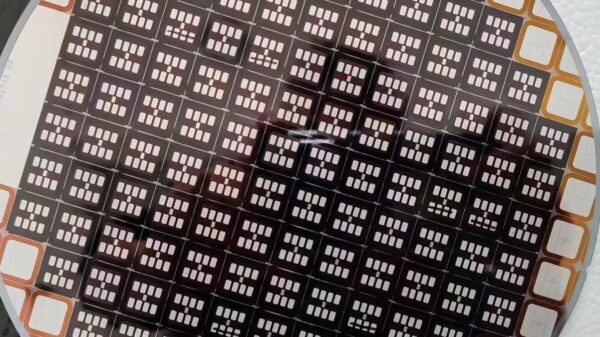

Amid the surge of the new energy wave, China has emerged as a critical juncture for the entire industrial chain. At the industry's core, power batteries in China account for over 60% of the global market share, birthing several globally influential enterprises.

Recently, public new energy battery companies have disclosed their performance metrics. Notably, Guoxuan Hi-Tech's 2022 annual report and first-quarter report reveal impressive growth. The company's revenue for 2022 exceeded 23.052 billion yuan ($3.22 billion), marking a 122.59% year-on-year increase. Operating profit reached 199 million yuan ($27.86 million. . .