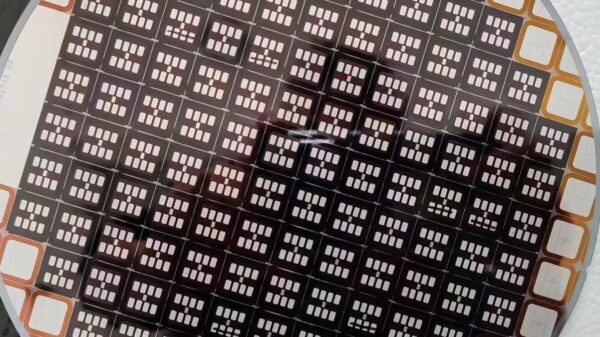

In an effort to secure a foothold in the burgeoning battery market, Jarvis has successfully developed a cutting-edge 3D computed tomography (CT) inspection equipment. The high-tech firm aims to establish a client base within the year, offering innovative inspection tools applicable to cylindrical batteries of specific dimensions (46 mm in diameter and 80 mm in height).

Ramping up its venture into the battery sector, Jarvis has begun supplying its inspection tools to Blue Oval SK, a joint operation between SK on-Ford and EV batteries. With the potential of attracting 3D CT clients, the firm's battery inspection. . .