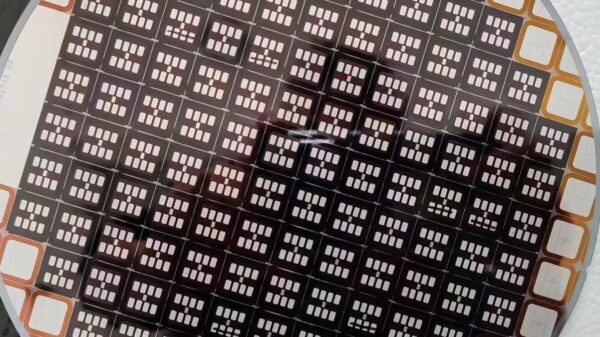

Dyson, the renowned British home appliance company, is set to produce its own batteries, forging partnerships with South Korea's battery industry, encompassing materials, parts, and equipment. Dyson's plan includes manufacturing small pouch-type batteries, primarily for devices such as smartphones, tablets, and laptops, at a facility in Singapore. Although the production capacity remains undisclosed, industry insiders estimate it to be around 1 GWh.

Established in 1991 in England, Dyson gained prominence for its innovative wireless vacuum cleaners, air purifiers, and hair dryers. The company relocated its headquarters to Singapore in 2019 amidst the Brexit turmoil. In 2022, Dyson. . .